engineering & customizing

BY MAATS

maats CAN EITHER ASSIST IN THE DIFFERENT AREAS OF DEVELOPING AND CONSTRUCTIon OR PROVIDE YOU WITH THE COMPLETE PACKAGE. MAATS HAS THE EXPERIENCE AND TECHNICAL EXPERTISE TO HELP CUSTOMERS WITH DEVELOPMENT AND CONSTRUCTION OF NEW AND INNOVATIVE MACHINERY BASED ON SPECIFIC NEEDS. OVER THE YEARS MAATS HAS DESIGNED, BUILT AND CUSTOMIZED NUMEROUS MACHINES TO MEET CUSTOMERS’ DEMANDS.

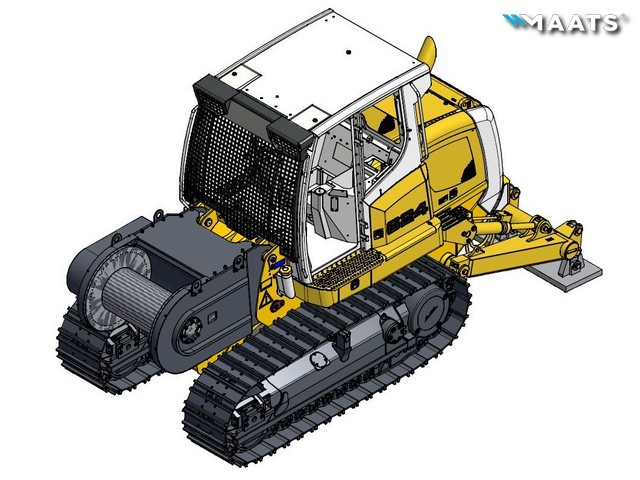

Another illustration of engineering excellence is the MAATS RL24 pipelayer. A machine that has now been replaced by the MAATS RL26. Liebherr's proven technology is used in this model's powertrain, electronics, and operator environment. Structurally, the machine has been extensively re-engineered to meet the highest requirements of Maats. Maats is still running RL24 pipelayers in the rental fleet. On request it is still possible to manufacture RL24 units when a solid core machine - the LIEBHERR PR714 or equivalent JOHN DEERE 700J - can be sourced.

The introduction of the new LIEBHERR PR716LGP bulldozer - which acts as a base machine for the MAATS RL26 - inspired the Maats engineers to initiate development on a multimachine and a pipecarrier unit. Although in the very early stage of conception there is potential in these models on a global scale. These units would meet the latest emission and safety standards and would be manufactured in-house by Maats.

Customizing

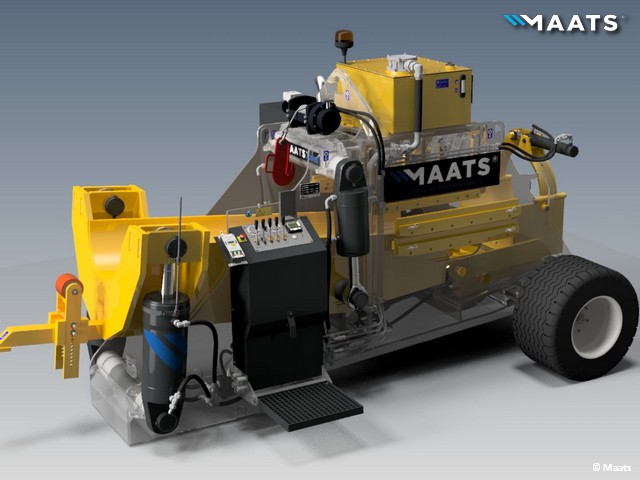

Modifying existing base machines into a specialised product is another skill of Maats. An example of the proficiency is the MAATS WR624 mobile winch.

Based on a LIEBHERR track loader this unit is deployed on oil fields for stabilising drilling equipment.

Besides forward winching, Maats can also supply machines for winching over the side.

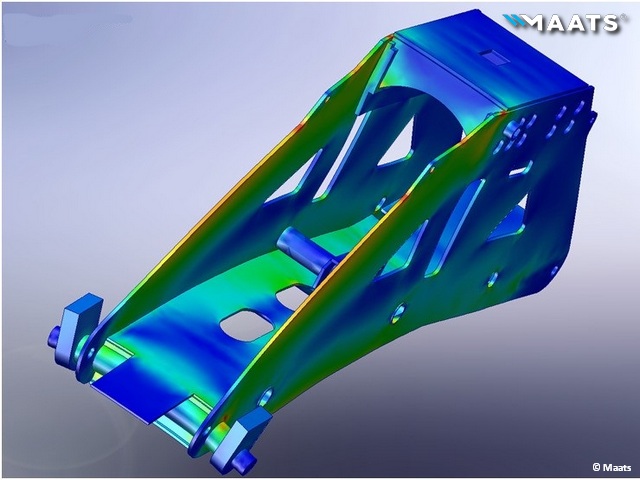

Based on existing LIEBHERR Pipelayers, Maats has engineered and supplied conveyor belt shifters.

Although the base product is already very capable, the shifting of conveyor belts imposes different levels of stress on the base machine and need to be adapted to prevent damage to the conveyor belt when repositioning.

Besides customizing complete machines, Maats is also capable of modifying attachments. An example is padders that have been re-engineered by Maats to enable attaching to a pipelayer.