internal bending

BY MAATS

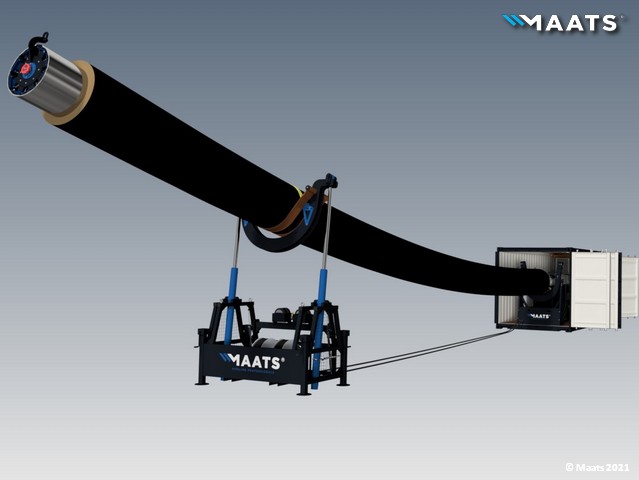

The MAATS internal bending machine is the first pipe bending machine in the world that is able to cold bend steel pipes from the inside, a technique ideal for pipes that have an external insulation, like those used for district heating and – cooling, for heated crude oil lines or for any other medium that has to remain within set temperature limits.

The MAATS internal bending machine provides a high-quality alternative for factory made bends or external bending that was previously used for thermal insulated pipes. It offers an improved flexibility and economy for any project using insulated pipes, anywhere in the world. Maats holds all patents for this unique machine.

Quality

When bending insulated pipe joints from the inside, the foam insulation and PE jacket pipe are left undamaged and therefore insulation values remain uncompromised.

The internal bending process has no effect on any leak detection wires or ducts for heat tracing cables being used.

Safety

The MAATS internal bending machine does its work from the inside of the pipe, this has the major advantage that there are no moving parts outside the pipe during the bending process. Another advantage is that the pipe joint is fixed into position during the bending process, largely reducing pipe handling operations with all related risks, throughout the process. As the bending process itself is largely automated, the risk of human error is minimized.

Flexibility

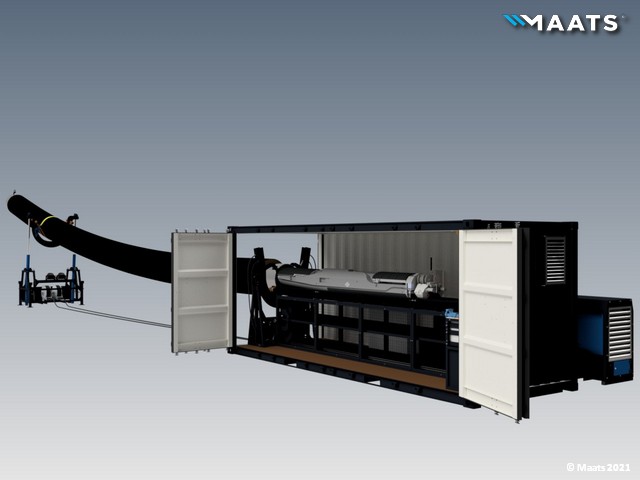

The MAATS internal bending machine itself is conveniently built inside a standard 20’ container, making it easy to ship not only to a jobsite, but also to relocate on a jobsite.

The well thought out and compact layout makes it possible to start bending quickly after arriving on site. Because standard pipe joints (up to 18 meters in length) can be bent, it is easy to adapt to unexpected changes in routing or terrain conditions.

Economy

The process of making factory bends is time consuming and costly and shipping bent pipe joints is much more expensive than the transport of straight joints. External bending, when technically viable, can only be done when using pipe joints with higher density foams, making pipes not only more expensive but also creating the need for a second pipe production line, a separate storage and separate quality controls. On top of that the coating will be damaged. The MAATS internal bending machine enables a project to basically have only standard straight pipes supplied for bending. It can bend up to 12 joints per day, depending on pipe length, pipe diameter, wall thickness and steel grade.

Highlights of the MAATS internal bending machines are:

- Bending on site

- Substantial bending angles

- No damage to pipe or pipe insulation

- High mobility and flexibility

- Cost effective

- Computer assisted and monitored cold bending process

Currently Maats manufactures two models:

MAATS IB18-24 for pipes ranging from 18" to 24"

MAATS IB28-32 for pipes ranging from 28" to 32"

The Maats engineering department is currently construction a third variant, the MAATS IB24-28 that is suitable for pipes ranging from 24" to 28".

The MAATS internal bending machines are only available for rent

MAATS internal bender - Patent nr. 10,441,987.